Hotel

Preventing from ingressIn the objective wells, massive water infiltration was occurred. The joints were injected through by sealing material based on the Polyurethane. After injecting, the insulation braces in two layers were applied.

Lift well

Preventing from ingressIn the objective wells, massive water infiltration was occurred. The well was cut down up to the carrying base. The joints and passages were injected through by sealing materials based on Polyurethane. After injecting, insulation braces in two layers were applied.

Store spaces

Industry floor with levellingOriginal marmot and ceramic pavement was ground by diamond. Special thixotropic Epoxy was applied as a connecting bridge. Levelling was used to flatten the spaces. The surface was penetrated repeatedly. The walkway layer was created by Epoxy by RAL 1001 required by the investor.

Polyfunctional object

Joint-free industry floor of light colourScreeding was ground by diamond grinding machine. The floor was penetrated and poured by sand. After hardening, the layer of UV table resin based on the Epoxy was applied. The investor required light futuristic shade.

Garage

Reconstruction of the object wallsThe garage showed ingress. The original concrete was incohesive. The masonry should be statically linked with strength injection, which serves as water-proof barrier simultaneously. Insulation braces in two layers were applied to the base. Reconstruction plaster was applied to the walls.

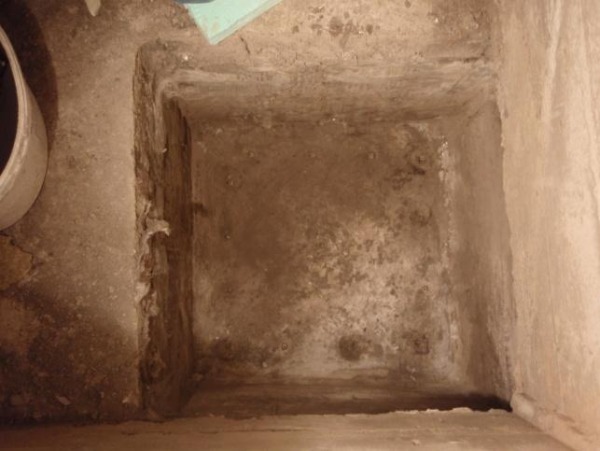

Villa

Preventing from ingress into basement spacesThe basement showed ingress on the level of contact of walls with the floor. The injection was performed because of statical linkage of bricks and following preventing from ingress. After injecting, special insulation on internal wall was applied.